Exploring the intersection of spaceflight history, pop culture, and space art.

In the previous edition of Creating Space, I took a look back at some historical concepts for recovering and reusing booster rockets and spacecraft. This time, I review how SpaceX got started and the progress they have made, and as an added bonus I bring you along for a very special visit to the Falcon booster refurbishing facility at the Kennedy Space Center in Florida.

Are you new to Creating Space? It’s the NERDSletter that explores the intersection of spaceflight history, pop culture, and space art. You can find this and all past posts at creating-space.art.

Remarkable Recoveries

As I wrote in the last post, the road to rocket reusability can be traced back to the 1950s. Engineers conceived of a variety of creative ways to recover and reuse booster rockets and spacecraft. Very few of those concepts crossed the boundary from idea to reality. But, in recent years, there has been a renewed thrust toward realizing that dream. Of the companies that have tried and succeeded in recovering their booster rockets for reuse, SpaceX was the first to be widely successful at doing it.

While Creating Space focuses mainly on spaceflight history, it is worth talking about the remarkable success SpaceX has had in recovering and reusing its rockets. Say what you will about their CEO, one cannot deny that they have turned the space launch industry on its head, obliterating many of the preconceived assumptions about what was impossible, or at least out of reach.

SpaceX has, over time, been increasingly successful in recovering its rocket parts for rapid reuse. They began by landing their first stages tail first on autonomous drone ships in the middle of the ocean.

Stop and read that sentence again and pause for just a moment to appreciate what an unbelievable string of words that would have been, on so many levels, to someone growing up in the early space age.

Now watch the video. It may seem somewhat normal now, but I remember seeing this for the first time and my brain was trying to make sense of a rocket appearing to lift off (or on) backwards!

Then, they succeeded in flying those same first stages back to their launch sites and making pinpoint landings on pads with ‘X’s marking their spots. You’ve got to hand it to SpaceX – they know how to do things with style.

The drone ships have those same Xs, too, by the way, as if some pirate’s treasure was resting beneath on the ocean floor.

As if these previously-thought impossible feats were not incredible enough, SpaceX’s next trick was to land the boosters TWO AT A TIME! I will freely admit to being gobsmacked when I first witnessed via the live video stream dual autonomous landings of the first Falcon Heavy boosters to be recovered in this way. And, yet, it is a testament to SpaceX’s ingenuity and tenacity that achievements like this somehow seem so matter-of-fact and expected, now. By the way, as these two boosters were being recovered, the third, central, booster of the Falcon Heavy was heading toward a successful landing on a drone ship at sea.

When not launching Crew Dragons, Falcon 9s are put to good use sending satellites into Earth orbit. Such unmanned payloads require fairings to protect them from the onslaught of air resistance during ascent through our atmosphere.

For a short time around 2020, SpaceX was catching the parachuted payload fairings in ship-mounted nets. (Again, think about what that sentence might have sounded like to someone in the 1960s ... even if they might have been familiar with this music.)

Eventually, they determined that merely letting the fairings land in the water and lifting them aboard the boats by crane was sufficient.1 The refurbishment consists of washing away the salt water and repairing any minor damage that may have occurred during flight and splashdown. SpaceX is a true learning organization, and they are continually making improvements to their design and manufacturing processes. As a result, the cost and time for refurbishment is continually being reduced.

Seeing How the Sausages Get Refurbished

In the June 2024 issue of Creating Space, I shared my trip to the Astronaut Scholarship Foundation’s (ASF) U. S. Astronaut Hall of Fame celebration events in Cocoa Beach, Florida. As a special part of the itinerary, SpaceX hosted a tour of ‘HangarX’, their refurbishing facility on the grounds of the Kennedy Space Center.

It was a truly spectacular experience. During my engineering career I became used to seeing large passenger airplanes being assembled in the factory. And, although I have seen various rockets up close in museums, I had never been inside an active rocket factory.

It was in the lobby of HangarX that I received my first taste of the true scale of the Falcon 9 hardware. Here I am standing 6-foot 4-inches tall next to one of the grid fins that help guide the first stage to its designated landing point.

I had previously seen one Falcon 9 launch in person from several miles away, and many more via online videos. I don’t know why, but I had imagined the Falcon 9 as being much smaller. My erroneous perceptions would further be corrected once I entered the factory.

HangarX is divided into two main refurbishing sections. The ASF tour group was first brought into the area where SpaceX refurbishes their payload fairings. We were not permitted to take photos within the factory, so I will be relying upon photos sourced elsewhere.

This SpaceX photo gives a true sense of the scale of the Falcon 9 payload fairings. They are listed on the SpaceX website as being 43 feet (13.1 m) in height and 17.1 feet (5.2 m) in diameter.

As a rough comparison, here is a 48-foot long (14.6 m) Meridian 459 Motoryacht, just five feet longer than a Falcon 9 payload fairing.

In the massive high bay, the fairings paradoxically seemed like small bathtub boats. At the same time, I felt dwarfed by the huge work volume as well as the fairings. If the fairings were bathtub boats, then I was a tiny toy passenger at the dock.

It is a good thing I didn’t know what was coming up next, because I would have been chomping at the bit to get out of the room full of fairings and into the next section they brought us into. The sight to come turned out to be a jaw-dropper for me.

We were led to the back of the fairing bay and through a small people-sized door to a deceivingly small corridor that I thought would lead us past some work offices. But, then my eyes were captured by what I saw looming above me.

This photo of a Falcon Heavy, consisting of three Falcon 9 first stages, will give you a good impression of what I saw. Looming overhead were the business ends of four or five Falcon 9 first stages, all having flown several times as evidenced by the dark soot covering them. Each stage was packed with nine Merlin engines looking like cannons ready for a serious fight, ready to pour a total of 1.71 million pounds (7,600 kN) of thrusting force out the back end when fueled and back on the launch pad.2

My immediate reaction to what I saw was exactly like Hayley Arceneaux’s on her Inspiration 4 flight when they opened the hatch to the cupola.

The Falcon 9 boosters were laid out in parallel covering the expansive workspace floor. Each one was suspended some six or seven feet (roughly 2 m) above the floor by large tooling fixtures on each end. The supports allowed the boosters to be rotated for easier access. While our tour was being conducted, SpaceX workers were busily inspecting the boosters, giving special attention to every minute detail, using bright flashlights to illuminate rivets from various angles.

The soot resulting from multiple launches and landings was readily apparent on the boosters. Lighter areas interrupted the gray sooty areas where the liquid oxygen (LOX) tank frost and retracted landing legs cover the booster bodies as they descend through their own exhaust on their way to their landing locations.

An interesting tidbit was shared by our guide regarding the SpaceX logos. They had originally been painted slightly higher up on the rocket. But, the frost around the LOX tank covered the ‘S’, so they repainted the logos slightly lower down on the body so the entire ‘SpaceX’ could be seen while the rocket was fueled. That’s the perfect combination of perfectionism and vanity, if you ask me.

The engines show their use by being blackened, as well. As far as I could tell (the question did not occur to me at the time), the engines may be inspected and refurbished in place while still attached to the rockets. I saw no evidence of removal of the engines during our tour.

As our tour guide shared details and took questions from the group, she led us from the bottom ends of the boosters to the top ends. The landing legs were detached from the boosters and were laid out just beyond the top ends. We were able to get extremely close to one of the legs – within touching distance, in fact, but I restrained myself out of respect and a little bit of fear of getting thrown in SpaceX jail.

Here again, I was caught by surprise at the legs’ large size. Without context, it is easy to underestimate the size of large machines. But, seeing the legs up close and in person, they struck me as very large canoe-like objects. This photo provides a human for scale (if you can find him).

The timing of events that week worked out very well on several occasions. On the way to the ASF U. S. Astronaut Hall of Fame gala at the Saturn V Center our bus was briefly stopped providing us a front row seat to watch as one of the recently refurbished Falcon 9 first stage boosters crossed our path on the way to its launch site. Here is a photo taken from my seat on the bus.

A day later, I was fortunate enough to witness the nighttime launch of a Falcon 9. This was the second Falcon 9 launch I have witnessed, but until that evening I had never seen any rocket launch at night.

My view of the launch was from the Cocoa Beach hotel room about 15 miles (24 km) miles south of the launch site. The rocket’s southeast heading brought the graceful arc of the flight directly across the room window’s oceanfront field of view from left to right.

The long yellow exhaust flame was the only thing visible as the Falcon 9 ascended. I was able to feel the window pane vibrate while hearing the rocket’s rumble (albeit somewhat muffled). From the room’s fourth floor location, I was able to follow the flight through the separation of the first stage and see the point of light from the second stage engine pass over the horizon. The initial reignition of the first stage was also visible as it redirected itself toward its landing on the drone ship.

Three days later, I saw the booster returning to Port Canaveral on the drone ship. From there, it would be brought back to HangarX to begin another cycle of reuse.

One last note: The subtitle of this article refers to SpaceX achieving the ‘Holy Grail’ by virtue of their success in reusability. SpaceX has demonstrated repeatedly reliable launch, recovery, and reuse of their Falcon first stage boosters, payload fairings, and their Dragon capsules. They have not yet recovered any second stages, and, of course, the Dragon capsule ‘trunks’ are left behind to burn up in the atmosphere.

So, strictly speaking, they have yet to achieve full rocket and spacecraft reusability – the figurative Holy Grail. But one might be tempted to give them credit for reaching the ‘Holy Trinity’, in a manner of speaking.

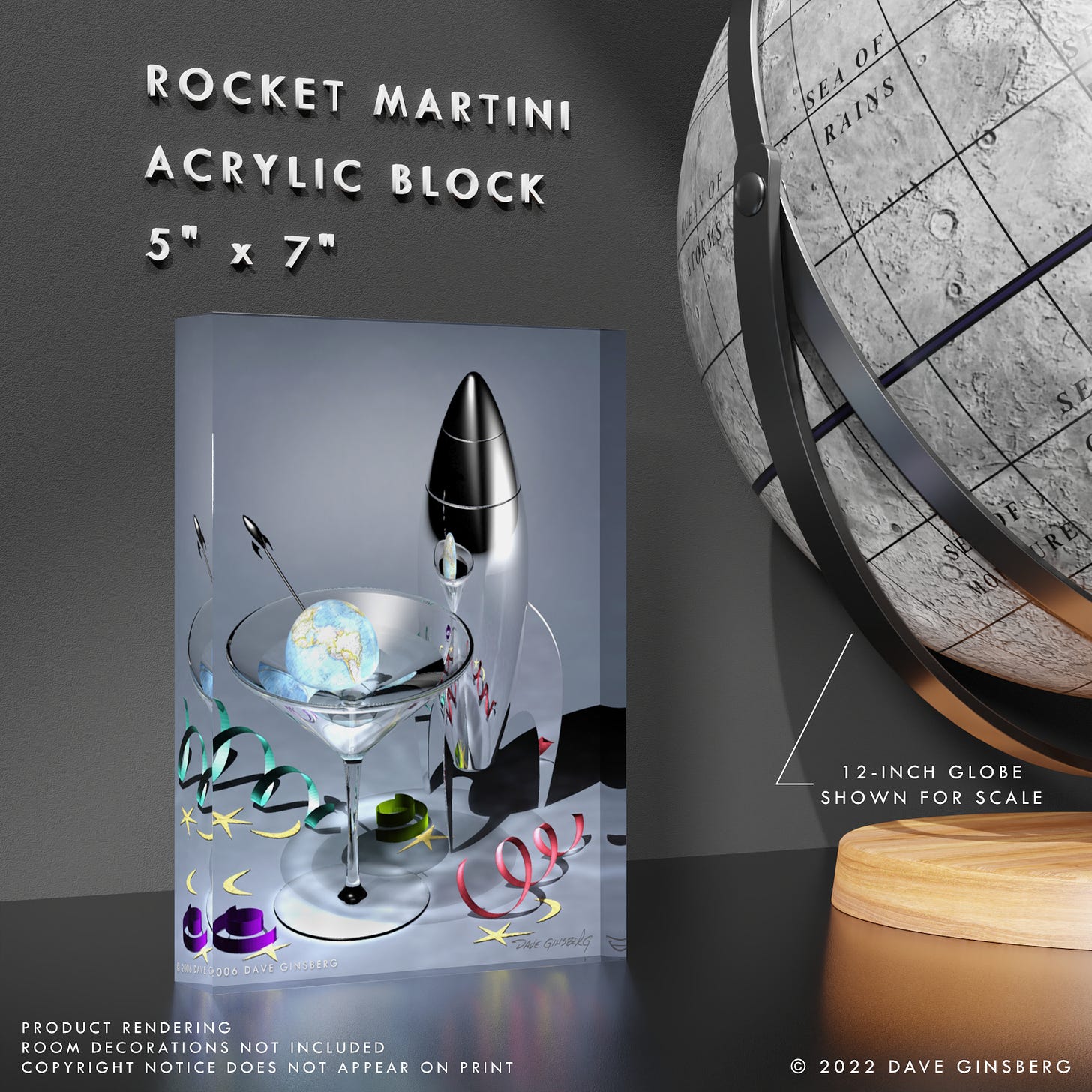

Merch of the Month

Rocket Martini Acrylic Block

Land this festive rocket martini custom acrylic block print on your space bar and reuse it for all your special occasions.

As a special thank-you for reading Creating Space, I am offering a discount on my artwork. Simply use code CREATINGSPACE15% for 15% off your entire order from the Pixel Planet Pictures shop.

My space-inspired art portfolio can be found at pixel-planet-pictures.com. You can also follow me on Instagram (pixelplanetpics).

Do you know fellow Space Geeks who might enjoy Creating Space? Invite them into this space, too!

Did you miss a post? Catch up here.

If you enjoyed this article please hit the ‘Like’ button and feel free to comment.

All images and text copyright © Dave Ginsberg, unless otherwise noted. All rights reserved.

SpaceX fairing recovery program, https://en.wikipedia.org/w/index.php?title=SpaceX_fairing_recovery_program&oldid=1236713178 (last visited Sept. 27, 2024).

Falcon 9 (https://www.spacex.com/vehicles/falcon-9/)

So jealous of your HangerX tour.

Dave that was a fantastic trip! I would have loved to have been there to see and learn what you did! Thanks for stepping outside the Creating Space format for this story! It is an amazing story you got to experience. The photo's are awesome. The size of the vehicles sounds small, especially when you think horizontally on the length but when you put the vehicle vertical then the scale becomes mind numbing! That's for adding those photos! Keep your memories of this written down and in 30 or so years this will be a story for Creating Space. Current events eventually become history.